Sonovia’s D(y)enim® Offer

Established Excellence

Our methods & technology have been validated in lab settings and industrial applications at Pure Denim.

Our 2 Pillars of Technology

One time

Engineering Support

We engineer the perfect dyeing machine to be added to the slasher dyeing line & provide extensive assistance during the one-time machine implementation phase.

Recurring

Green Chemistry Supply

Our partners have the chance to be at the forefront of eco-innovation in the textile sector with our unique green chemistry.

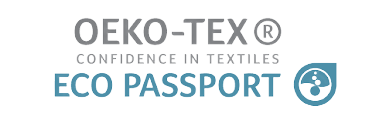

The Ultrasonic De(Y)nimSolution

LCA Reports

Key Benefits

Sonovia Tackles Top 5 Sustainability Challenges:

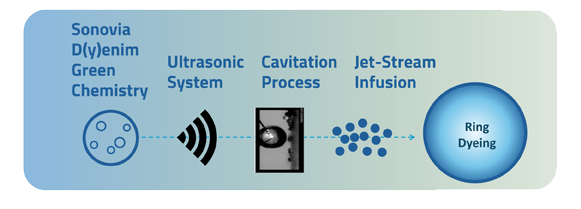

85% Water Saved

Significantly reducing water consumption in the dyeing process.

100% Toxic Chemical Elimination

Embrace a cleaner environment for workers and the planet by eliminating harmful chemicals.

60% CO2 Emissions Reduction

Combat air pollution with a significant decrease in greenhouse gas emissions.

100% Production Waste Eradicated

Reduce environmental impact by eliminating waste and streamlining production.

92% Less Land Use

Lower need for land by significantly minimizing machine footprint.

Certifications

Our Services

Dyeing machine Engineering

Tailor made Ultrasonic Dyeing Machine

Established

Excellence

Our methods have been validated in lab settings and industrial applications at Pure Denim.

Full-Spectrum

Support

Providing extensive assistance and collaborative engagement during the entire implementation.

Sustainability Leadership

Partner with us for a chance to be at the forefront of eco innovation in the textile sector.

Frequently Asked Questions (FAQ)

Who are we?

We are a textile-tech company developing the next generation of high-performing and sustainable ultrasonic textile dyeing and finishing. By providing an innovative and comprehensive solution, we, at Sonovia, aim to reshape the textile industry, and set new standards for sustainable, high-performance, long lasting and cost-effective production.

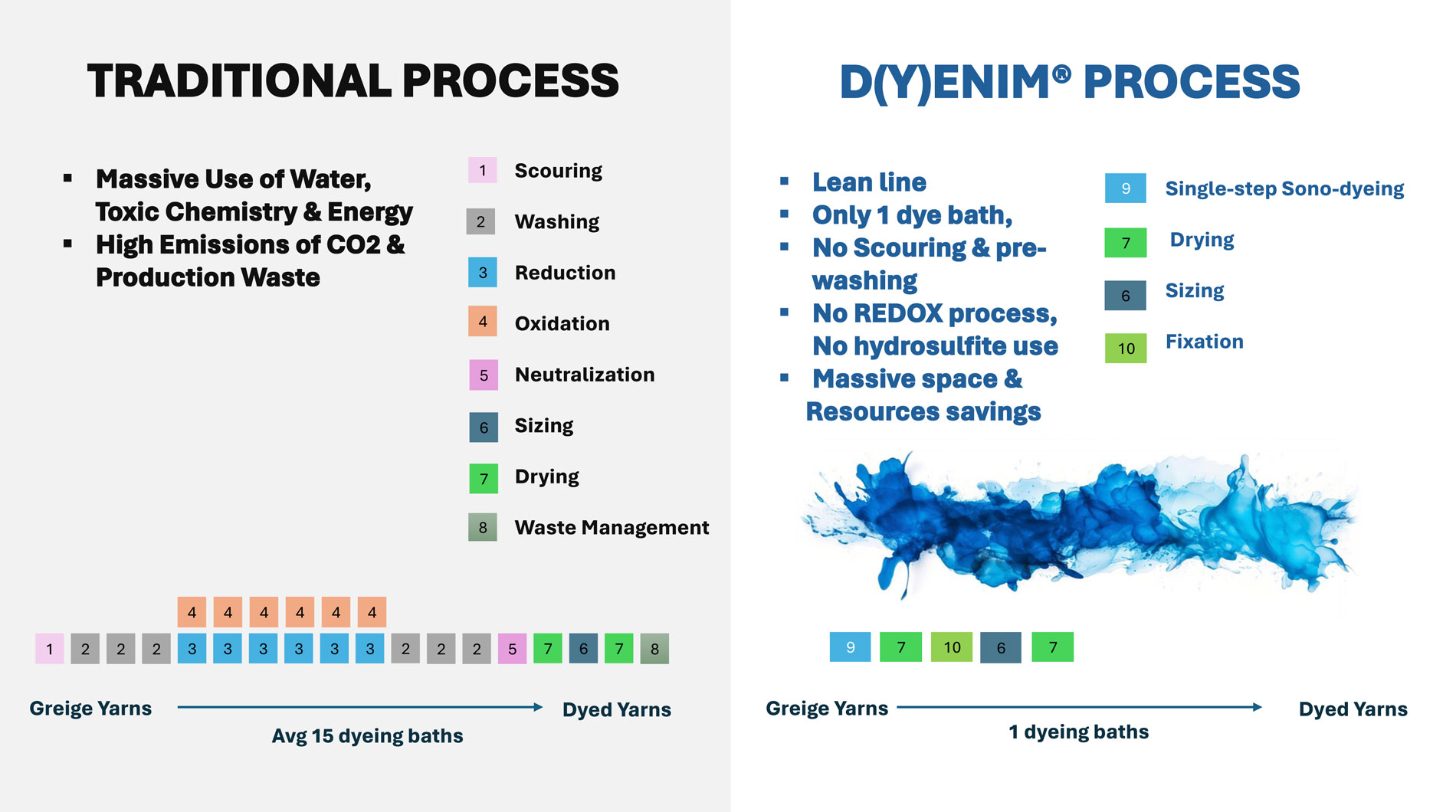

We utilize ultrasonic cavitation implosions to physically embed our specially formulated chemicals onto cotton yarns, resulting in sustainability, high performance, and cost efficiency.

- 85% reduction in water consumption with only 1 dye bath.

- 60% reduction of CO2 emissions, due to lower energy requirements, reduced water heating, and a more streamlined operation that relies less on fossil fuels.

- No pre-or post-dyeing preparation and washing required.

- 100% reduction in toxic chemicals by using Zero-Toxic water-based dye chemicals.

- 100% elimination of production waste.

- Reproducible and controllable dye shades.

- Simple integration into existing lines.

- 92% reduction of land use through the use of compact and efficient machinery, as well as the elimination of large-scale waste treatment facilities.

While production methods differ, we strive to offer competitive pricing comparable to other methods.

The dyeing process is lean, cost-effective, eco-friendly, and hassle-free.

SonoDye introduces groundbreaking technology set to transform fashion. Its primary targets are spinners, who will benefit from reduced resource usage and cost savings. Additionally, brands and retailers can achieve sustainability goals faster, meeting the demand for eco-friendly products.

What do we do?

We master the use of ultrasonic cavitation jet-streams to effectively impregnate cotton with desired chemistries.

Our SonoDye groundbreaking technology is replacing slasher dyeing rope by using only 1 dyeing bath.

The SonoDye machinery is great cost-competitive, fast and easy to integrate to existing lines.

Extensive research, testing, and experience have led us to achieve identical results between denim treated with the SonoDye process and denim treated with traditional dyeing methods. In other words, SonoDye-treated denim offers the same color and handfeel as denim dyed using conventional techniques.

We utilize yarns ranging from NE 7.5 to 16, including both ring-spun and open-end yarns.

SonoDye’s current focus is on treating denim yarns due to the substantial market opportunity it presents. However, the technology holds promise for a wider range of cellulosic natural fibers, including linen, rayon, hemp, and jute. Our ongoing R&D efforts actively explore these potential applications.

SonoDye utilizes a 100% zero-toxic, water-based dye chemistry, completely eliminating the use of harmful chemicals. Additionally, SonoDye holds the Bluesign certificate.

Contact Information

For general inquiries and communication, please use any of the following methods:

- Website Contact Form: Fill out the form available on our website.

- Email: Send us an email at info@sonoviatech.com

Investor Relations:

For investor-related inquiries, please contact:

- Shay Hershcovici

- Co-Founder & CIRO

- Listed in TASE: SONO

- Phone: +972 508431473

- Email: shay@sonoviatech.com

Sales Department:

For sales-related inquiries, please contact:

- Annabelle Evenhaime

- Chief Sales Officer

- Phone: +972 524294802

- Email: annabelle@sonoviatech.com